Colorful Screen Dishwashing Series

High-end Dishwashing Dispenser System

XWJ-2 series is a high-end dishwasher dispenser system equipped with an LCD color touchscreen, seamlessly integrating status monitoring, program scheduling, data analysis, maintenance reminders, remaining-barrel alarms, and various washing functions.

XWJ-2 loT Color Screen Dishwasher Dispenser

NEWSPAPERS

Scope Of Application

The XWJ-2 Dual-Pump Dishwasher Dispenser System features a high-definition color display and is engineered for heavy-duty washing applications. Available with either a peristaltic pump or a maintenance-free electromagnetic diaphragm pump, it offers the ultimate solution for every scenario.

Hardware Features

-

Equipped with a high-resolution LCD color touchscreen, seamlessly integrating advanced functions such as status monitoring, manual tuning, data analysis, maintenance reminders, and remaining-barrel alerts.

-

Through a newly customized operating system, users can intuitively monitor critical status information on the main screen, including concentration, temperature, rack count, chemical usage, and alert prompts.

-

The mainboard integrates a high-performance digital chip design supporting an adaptive conductivity-based concentration analysis system, intelligently maintaining solution stability.

-

Standard configuration includes a high precision peristaltic pump unit with PUM roller technology, significantly reducing compression resistance and extending tube life.

-

Optional electromagnetic diaphragm pump unit offers superior pressure resistance without tube replacement, greatly lowering maintenance costs.

-

Remote access via smartphone or PC to the SPLANEY IoT app enables status monitoring, data analysis, and program scheduling, facilitating convenient washing operations.

-

Manage detergent concentration levels remotely through the app to optimize water and chemical usage, reducing cost and boosting efficiency.

-

The minimalist exterior design can be customized with your company name or logo to establish brand identity.

-

The complete unit is certified under multiple quality systems, including EU CE, SGS, and ISO9001.

Software Features

-

Offers multiple modes—time mode, flow mode, and probe mode—to ensure versatility across various scenarios.

-

Automatically adjusts pump run time based on preset concentration ranges, stopping immediately if values exceed limits.

-

Includes pump flow measurement functionality to auto-calculate chemical flow data, significantly reducing dosing errors.

-

Introduces a descaling reminder function — when the sensor probe requires cleaning, a pop-up alert will automatically appear on the main interface.

-

Intelligently calculates real-time/average barrel usage and remaining-barrel days; highlights the main screen when supply is low.

-

Automatically aggregates operational data—chemical usage, cost, and wash rack count—for review on the color display.

-

Logs critical operations—power on/off, parameter adjustments—in real time to ensure process safety and transparency.

-

Supports maintenance-cycle display for dozens of accessories, enabling users to monitor replacement schedules.

-

Allows setting the detergent pump to run automatically on first start-up each day for initial machine cleaning.

-

Provides multiple pump interface options—including British and American standards—to meet regional requirements.

Touchscreen Feature

Ware UI 3.0 Touchscreen System

|

Accessories

ND-20 Dual-function Integrated Probe

The dual-function integrated probe is a smart sensor designed for dishwasher dispensers, tracking detergent/rinse aid concentration and temperature in real-time. Its compact design saves space, ideal for small chemical containers.

-

Equipped with precise conductivity probe (250μS-5mS) for continuous monitoring of concentration and temperature.

-

Housing of corrosion-resistant plastic maintains performance over long-term use.

-

Integrated temperature and concentration sensor design saves installation space.

DXF-20 Corrosion-Resistant Check Valve

The DXF-20 Series corrosion-resistant check valve, designed for precise chemical suction, is available in reciprocating and diaphragm versions. It reacts quickly to fluid changes, features a built-in filter, and uses a ceramic counterweight for versatile applications.

-

Built-in filter effectively captures large particles, reducing maintenance frequency.

-

Two structural options (reciprocating or diaphragm) to suit different chemical types.

-

Corrosion-resistant materials ensure compatibility with acidic and alkaline chemicals.

GD-40 Corrosion-Resistant Pipeline

The GD-40 Series dispenser-specific pipeline is made of corrosion-resistant materials, featuring a wide diameter and high flow capacity. It effectively withstands acidic and alkaline chemical corrosion, significantly extending its lifespan.

- Large diameter and high flow capacity to meet high-volume dilution needs.

- Thickened pipe walls enhance chemical resistance and extend equipment durability.

Chemical Barrel Wall-Mount Bracket

An optional wall-mount bracket is available for chemical Barrel. Its detachable design ensures a lightweight structure for easy transport, reducing logistics costs while maintaining flexibility and reliability in use.

- Fits two standard 1~5L chemical Barrel, with custom sizes available upon request.

- Detachable structure minimizes transportation costs.

Product Video

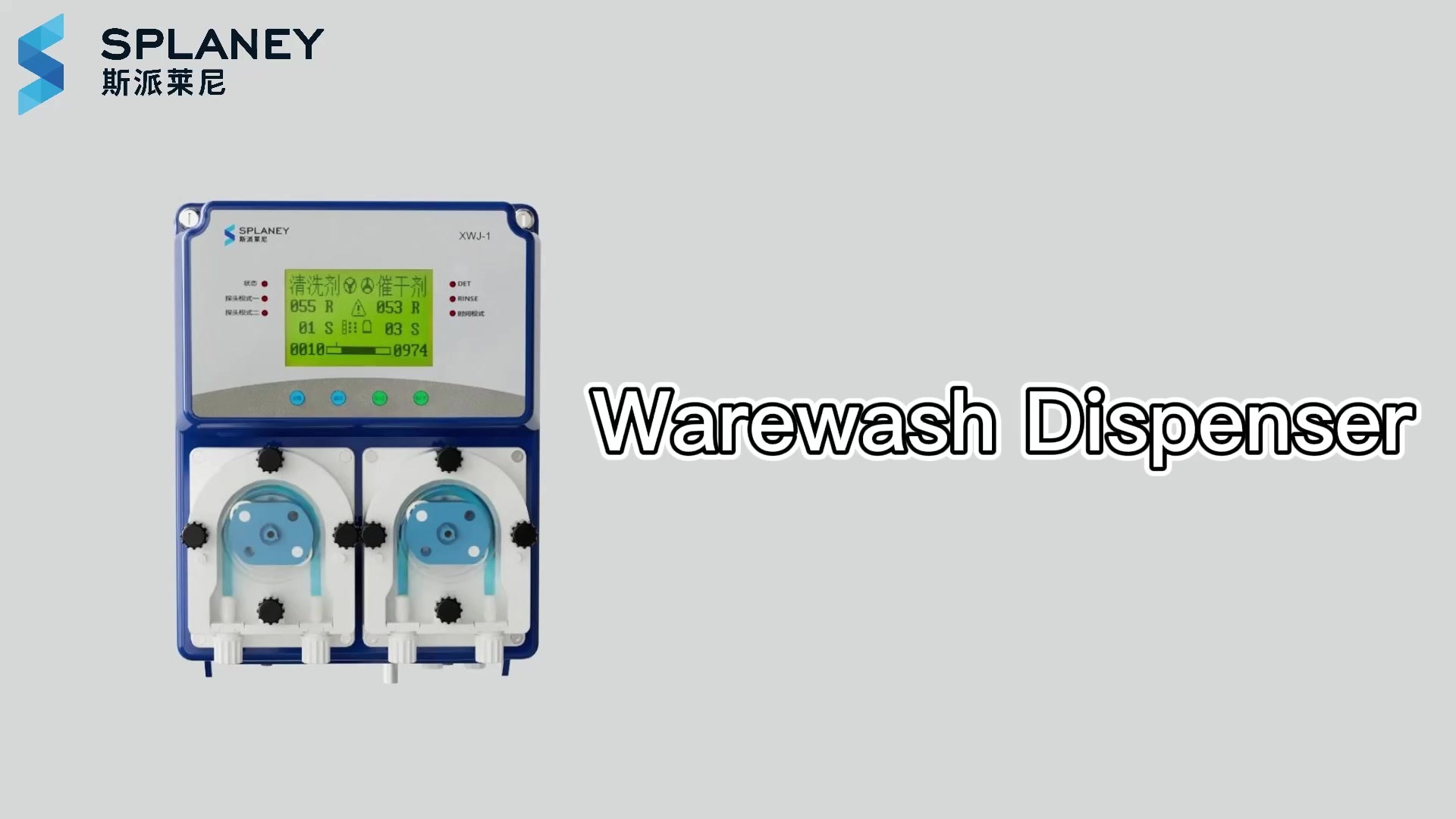

XWJ-1 Dishwasher Dispenser Demonstration